Case Studies

Evidence of Greenroof successes from across the country and around the world

Washington | Oregon | Australia | Hong Kong

Since the early 1960s, both green roofs and roofs with “ponded water” have been constructed using an HPI (Hydrophobic Pore-blocking Ingredient) technology that makes the concrete roof completely impervious. Click here for industry testimonials on the superior performance of this technology.

This waterproof concrete technology has been implemented primarily in Australia and Hong Kong. Beginning with simple concrete roof slabs for parking, truly waterproof concrete has been used to create ponded water, swimming pools, amenity and green spaces over habitable space. Particularly in Hong Kong, the scarcity and expense of real estate forced development to go upwards, with amenities such as swimming pools and gardens being constructed on rooftops. Waterproof concrete has been used successfully for many years in these applications.

Following are several examples of this technology applied throughout the world, fulfilling a wide range of structural and functional purposes. Most of these case studies have over a twenty-year history with no leaks.

Washington

Waterproof Concrete in the Northwest

Waterproof concrete technology has recently been introduced in North America. Projects include a large green roof with a small park over a parking structure in Redmond, WA. The designer had originally specified a ten-inch structural post-tensioned deck with a sandwich membrane, followed by a four-inch topping slab to protect the membrane. By using the waterproof concrete technology, the topping slab was eliminated and a nine-inch structural slab was sufficient. This significantly reduced the weight of the structure, allowing the engineer to eliminate several of the support columns, creating additional parking spaces while saving the owner just over $100,000 in initial costs and freeing his company from the possibility of eventually having to replace the membrane. The contractor was also able to carry out construction without worrying about puncturing any membranes or damaging any coatings.

Waterproof concrete technology has recently been introduced in North America. Projects include a large green roof with a small park over a parking structure in Redmond, WA. The designer had originally specified a ten-inch structural post-tensioned deck with a sandwich membrane, followed by a four-inch topping slab to protect the membrane. By using the waterproof concrete technology, the topping slab was eliminated and a nine-inch structural slab was sufficient. This significantly reduced the weight of the structure, allowing the engineer to eliminate several of the support columns, creating additional parking spaces while saving the owner just over $100,000 in initial costs and freeing his company from the possibility of eventually having to replace the membrane. The contractor was also able to carry out construction without worrying about puncturing any membranes or damaging any coatings.

In addition to grass and plantings, decorative concrete walks and an attractive patio with a gazebo highlight the green space over the parking area. The owners offer the added value of covered underground parking as well as a park-like setting while still satisfying fire access requirements. This structure has been in service for over two years with a very high degree of owner satisfaction.

Oregon Zoo

Waterproof Concrete in the Northwest

In Portland, Oregon, the Oregon Zoo elected to use waterproof concrete technology to create a new interactive salmon display. The entire building was cast-in-place waterproof concrete done without membranes or coatings, despite the fact that the roof is a part-water feature and part greenroof.

In Portland, Oregon, the Oregon Zoo elected to use waterproof concrete technology to create a new interactive salmon display. The entire building was cast-in-place waterproof concrete done without membranes or coatings, despite the fact that the roof is a part-water feature and part greenroof.

The entire building was cast-in-place waterproof concrete done without membranes or coatings, despite the fact that the roof is a part-water feature and part greenroof.

In addition, the walls of the building are half-submerged since they act as the pond in which the salmon are contained. Without a membrane to puncture, imbeds for the wire fencing were drilled directly into the roof of this structure, without worry of a leak.

Very large rocks were placed directly against the outside walls without any protection mats or devices. Other rocks are being created with a shotcrete carving mix containing the waterproofing system.

Australia

Waterproof Concrete Down Under

In 1962, field trials were conducted by the Engineering and Water Supply Department in tidal salt pans in the desert regions of Southern Australia.

Soil analysis showed very high levels of chloride and sulfate salts. These caused rapid deterioration.

After 30 years of exposure in the Sabkha salt pan, the waterproof concrete has remained virtually unaffected. Otherwise-similar ordinary Portland and sulfate-resistant cement concretes have all but disintegrated.

Completed in 1963, the roof of the original Cadbury Fry Pascal Factory in Collingwood, Australia is still being effectively waterproofed and protected with waterproof concrete. Ponded water on top of the building serves as thermal mass for cooling.

At the Cairns "Reef Casino" in Queensland, Australia, there is a suspended, landscaped rooftop atrium deck. This post-tensioned waterproof concrete deck supports the rooftop glass-pyramid atrium and is covered with soil, plants, and water features.

At the Coolangatta "Showcase on the Beach" in Queensland, Australia, the waterproof concrete podium deck and suspended swimming pool deck incorporate tennis courts, a landscaped roof garden, and recreational areas. This concrete is also protected against airborne chlorides for maintenance-free, design-life durability.

Hong Kong

Waterproof Concrete in Asia

Tuen Mun Town Plaza

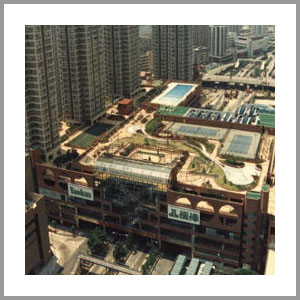

Tuen Mun Town Plaza

The 33,000-meter membrane-free podium deck of the Tuen Mun Town Plaza in Hong Kong incorporates a swimming pool, tennis courts, landscaped areas, skateboard track, and more, demonstrating the effectiveness of the waterproof concrete system. On this complex structure with many diverse rooftop uses, the architect saved eight weeks in design time by not having to detail any membranes. Construction was considerably faster as well, since the design was a simple structural concrete slab with the waterproofing built right in.

Pamela Youde Critical Care Hospital

Hong Kong’s Pamela Youde Critical Care Hospital—Three floors of habitable space below salt water cooling towers—Pink areas are protected by the Waterproof Concrete System.

In Hong Kong, potable water is very expensive. For the Pamela Youde Hospital, designers specified sea water to be used in the air-conditioning system’s cooling towers. The series of Salt Water Cooling Towers was constructed over three floors of hospital space. The bottom of the water containment tank is a waterproof roof over the Nurse’s quarters. Without maintenance and constant repair/replacement, high-temperature salt water would destroy normal reinforced concrete in a matter of years.

How to make the structure maintenance-free for its designed life?

Waterproof concrete was the answer. In Hong Kong’s tropical climate, it would be impossible for the hospital to function properly without constant state of the art air conditioning. Since this is a 24-hour, 365-day-a-year critical facility, NO allowance could be made to undertake structural maintenance in the future.

The concrete floor of the cooling towers forms the waterproof roof of the Nurse's quarters and other hospital areas three floors beneath. There is no corrosion of the exposed concrete beams and columns. With truly waterproof concrete, epoxy-coated or stainless steel rebar is not needed—salts and chlorides do not get into the concrete matrix. In 2004, after 18 years of non-stop service/exposure since the cooling towers were turned on, there is absolutely no sign of corrosion. ZERO maintenance has been required on any of the waterproof structural concrete. ZERO leaks have occurred in the Nurse's Quarters beneath the towers, despite constant repair, rectification, and even replacement of all the metal fittings on the cooling towers—even the stainless steel railings.